SHEARS GUIDE

SEE SPECIFICATIONS AND LINKS

STRAIGHT SHEARS | CURVED SHEARS | THINNING SHEARS

Selecting shears is one of the most important decisions a groomer can make. The shears you select will have a major impact on the speed and quality of your work, the health of your hands, and the state of your wallet! The information provided below will help you to better understand your options and choose the best tool for your grooming needs.

SHEAR TYPES

Straight Shears are used to set patterns, for shaping, and for finish work. See Specifications and Links for all Straight Shears.

Curved Shears are used to fine tune shaping and set angulation for specific areas. The larger the shear the more gradual the curve so the larger shears are better suited for larger dogs. See Specifications and Links for all Curved Shears.

Thinning Shears have a cutting edge on one blade and teeth on the other. Double thinners will have teeth on both blades. Thinners are used to give the groom a more natural look and to blend out or “erase” harsh clipper lines. See Specifications and Links for all Thinning Shears.

EDGE TYPES

Beveled/Serrated shears have tiny grooves or serrations that are ground into the edge of one blade holding the hair in place and increasing efficiency while grooming.

Hollow Ground/Convex/Honed has a ground-down inside that reduces weight and gives the blade a sharper edge for smoother and more precise cutting.

HANDLE TYPES

Opposing Grip is the standard design and is great for groomers who prefer to hold their shears with their middle finger and thumb.

Offset is a more ergonomic design. This style is designed to reduce hand fatigue. These are a wonderful option for groomers who prefer to hold their shears with their ring finger and thumb.

Swivel Thumb is where the thumb ring is free moving and will follow the motion of the groomer’s hand while scissoring.

SHANK TYPES

Short Shank has a shorter distance from the finger holes to the balance/pivot point. This allows the blades to open wider with less hand movement.

Bent Shank is when the shank from the balance/pivot point to the finger holes has been forged with a slight upward angle. This allows for greater ease of grooming without flattening the coat.

OTHER CHARACTERISTICS

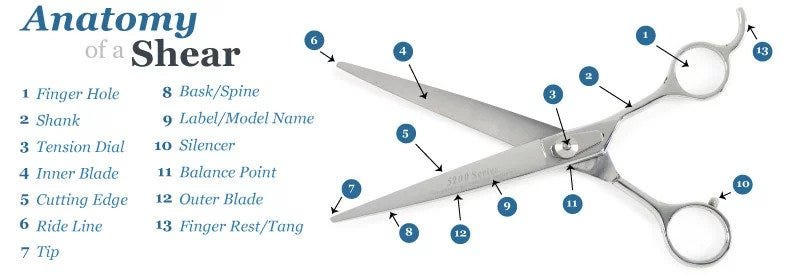

Length: Depending on the manufacturer, shears are measured from the tip of the tang (the finger rest) to the tip of the blades.

Rockwell Hardness Rating: is a scale used to measure how hard the metal is. The higher the number the better the shears can hold an edge, but the more brittle the metal will be.

MATERIALS

Carbon Steel is an alloy of hardened steel made from iron and carbon. This can be durable enough to hold a sharp edge very well but it should be always kept dry and oiled.

Stainless Steel is an alloy of hardened steel that includes a minimum of 10.5% chromium to better resist rust and corrosion. Stainless Steel has a number of variations on how it can be graded – 440A (Good), 440C (Better), and VG-10 (similar to 440C but even stronger).

Frozen/Ice/Cryogenic Tempered Steel is subjected to temperatures well below zero (sometimes down to -300oF) in order to obtain optimum hardness and allow for a cutting edge that lasts longer

TIPS FOR GROOMERS

Here are some things to keep in mind when choosing shears for your own collection.

- Shears are a very individual and personal tool, use the length and style that feel most comfortable to you.

- Keep in mind that even though 5 inch shears may be the most comfortable option for you when hand scissoring large breeds, they may not be the most efficient option for the task.

- If you have shears with a tension dial and need to make adjustments to the tension, bear in mind that tightening or loosening the dial too much could be doing damage to your shears.

- When a pair of shears has had their tension loosened too much, the blades will “flop” against one another making cutting difficult and creating nicks. This can cause hair to fold or scoot out of the tips.

- When the tension has been tightened too much on a pair of shears, the blades will “grind” against one another during usage, wearing the sharp edge off faster than normal and damaging the blades.